Sequencing batch reactors (SBRs), also known as sequential batch reactors, are activated sludge systems applied in wastewater treatment. SBR systems are upgrades of conventional activated sludge systems that minimize footprint by integrating separate functions in a single treatment system. Standard SBR setups usually include the reactor basin, water sludge draw-off mechanism, effluent decanter, and process control system.

How Do Sequencing Batch Reactors Work?

SBRs process wastewater in batches through single fill-and-draw tanks. Each tank operates under five commands of fill, react, settle, draw, and idle. Some treatment facilities may use two or more batch tanks in optimizing the effectiveness of their systems, depending on the expected volume of wastewater flow and treatment period. Influent water that passes through the SBR undergoes systematic grit removal screening processes before reaching the reactor tanks. Technicians partially fill each batch reactor with biomass to facilitate the anaerobic processes involved in water treatment. The wastewater undergoes various processes from within batch reactors, including aeration, equalization, and primary and secondary clarification, through a time-controlled sequence. Aeration is a crucial phase in wastewater systems, which involves adding oxygen to wastewater that feeds bacteria populations that stimulate the aerobic biodegradation of natural contaminants. Equalization or EQ is the process that balances the characteristics of wastewater, such as flow rates and p levels. The equalization processes reduce the errors and process adjustments required down-line in a treatment facility. Clarification processes eliminate the impurities from wastewater supplies to provide a clear appearance.Sequencing Batch Reactors vs. Standard Activated Sludge Systems

SBRs function similarly to other activated sludge systems, with the only significant difference being they perform all treatment processes from within a single tank. Unlike conventional activated sludge systems, SBRs do not receive a continuous supply of influent wastewater once the reactor is full.

The application of SBRs eliminates multiple components found in conventional activated sludge systems, which include return activated sludge and primary sludge pumps. Technicians only focus on a single sludge in an SBR setting for each treated batch of wastewater and have greater flexibility and control over treatment processes. Treatment facilities that implement sequencing batch reactors can significantly improve the quality of effluent flow by removing organic compounds through a sophisticated solids handling system that comprises a thickener and aerobic digester.

SBRs feature several disadvantages compared to less sophisticated activated sludge control systems, including high costs, complex maintenance, higher technical expertise, and potential flaws in equalizing and aeration processes that may require additional treatment procedures.

Industrial Uses of SBR

Facility managers usually implement SBRs in low-flow systems due to the limitations of their time-controlled processes. However, SBRs require minimal storage space compared to conventional activated sludge systems. As such, facilities may combine SBRs with additional reactors to create enhanced compound systems across various industries.Sewage Treatment

Sewage treatment plants may choose to incorporate sequential batch reactors due to their effectiveness in handling solids in organic wastewater. Research from Tsinghua University shows that SBRs could effectively break down thermally hydrolyzed sewage sludge.Enhanced Anaerobic Digesters

An SBR system can provide more control and efficiency in anaerobic digester outputs compared to conventional continuously stirred tank reactors. Studies show that facilities can meet effluent standards with improved control cycle duration and discharge operations by setting influence factors at appropriate levels.Mechanical Biological Treatment (MBT)

Mechanical biological treatment (MBT) facilities apply SBRs in routine biological treatment processes such as anaerobic digestion or waste separation. MBTs may play an essential part in biodegradable municipal waste treatment. The most common products of MBT facilities include biogas and recyclable products such as plastics and metals, and inert materials dumped in landfills.Reagents Used in Sequential Batch Reactors

SBRs involve a range of reagents to process multiple functions, such as biological treatment and chemical oxidations. Some examples of reagents used include:- Fenton’s Reagent: sodium hydroxide solution with ferrous iron catalysts, commonly used in oxidization applications for wastewater treatment.

- Folin & Ciocalteu’s phenol reagent: a solution to measure protein levels in aerobic sludge granulation techniques of wastewater treatment.

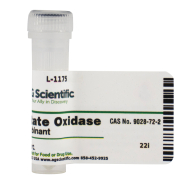

- Pyruvate Oxidase: a biomarker used in monitoring phosphate concentrations.

AG Scientific is a leading supplier of quality scientific products for a wide range of academic and lab settings. AG Scientific performs strict quality checks to ensure that you receive the highest quality of scientific products. We are your trusted ally in discovery. Visit our site to learn more about our quality items for your project requirements.

Additional Reading

- Water Remediation Electrochemistry

- Bottoms Up: Water Diagnostics and Testing

- Ion Exchange Membranes for Electrodialysis