Lactic acid is an end product of Glycolysis under anaerobic conditions. There are 2 optically active stereoisomers of lactic acid:

Lactic acid is an end product of Glycolysis under anaerobic conditions. There are 2 optically active stereoisomers of lactic acid:- L-Lactic acid produced by muscles during anaerobic glycolysis and by most of the lactic acid bacteria.

- D-Lactic acid Produced by some bacteria, plants and algae.

- Medicine Indicator of ischemia in critical care and indicator of inflammation.

- Sports medicine Testing and monitoring of training intensity and recovery.

- Food quality analysis - Testing food for bacterial growth and spoilage, fermentation marker.

Lactate and lactic acid fermentation play an important role in the food and beverage industry. The reason behind fermenting food is for preservation purposes. Lactic acid fermentation also prevents the growth of undesired bacteria and mold. Lactic acid is used as an emulsifying agent in bakery production. Lactic acid is also used in the chemical industry to produce biodegradable polymers, in cosmetics, pharmaceutical, leather and textile industries.

In some cases Lactic acid fermentation is an indicator of spoilage of food. The increased level of L-lactate in egg is an indicator of spoilage by contamination or incubation. Also in canned fruits and vegetables, UHT (Ultra High Temperature) milk the increase of L-lactate is the marker of spoilage. Contamination of fruit juices with lactic acid bacteria during production and storage leads to unacceptable standards for human consumption that causes economic losses for the producer and causes environmental problems.

The concentration of lactic acid is done by HPLC using UV/VIS or capillary zone electrophoresis. The lactic acid stereoisomers can be assayed independently by enzyme kits with stereospecific NAD+ dependent dehydrogenases. Another method of detecting lactic acid is the use of colorimetric test strips. The alternative method of testing lactic acid is the use of biosensors. Biosensors provide rapid, simple and direct measurement without the hassle of sample preparation.

A Biosensor is an integrated receptor-transducer device, which is capable of providing selective quantitative or semi-quantitative analytical information using a biological recognition element in direct spatial contact with transducer element. The first biosensor for lactic acid (L-lactate) was reported in 1970 by Wiliams et al. It was amperometric electrode with cytochrome b2 as biological sensing element with Fe(CN)63- as redox mediator.

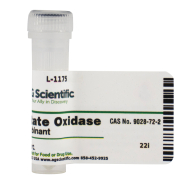

The most common biological receptor for L-lactic acid is L-lactate oxidase (LOD) which catalyzes the reaction:

Lactate and lactic acid fermentation play an important role in the food and beverage industry. The reason behind fermenting food is for preservation purposes. Lactic acid fermentation also prevents the growth of undesired bacteria and mold. Lactic acid is used as an emulsifying agent in bakery production. Lactic acid is also used in the chemical industry to produce biodegradable polymers, in cosmetics, pharmaceutical, leather and textile industries.

In some cases Lactic acid fermentation is an indicator of spoilage of food. The increased level of L-lactate in egg is an indicator of spoilage by contamination or incubation. Also in canned fruits and vegetables, UHT (Ultra High Temperature) milk the increase of L-lactate is the marker of spoilage. Contamination of fruit juices with lactic acid bacteria during production and storage leads to unacceptable standards for human consumption that causes economic losses for the producer and causes environmental problems.

The concentration of lactic acid is done by HPLC using UV/VIS or capillary zone electrophoresis. The lactic acid stereoisomers can be assayed independently by enzyme kits with stereospecific NAD+ dependent dehydrogenases. Another method of detecting lactic acid is the use of colorimetric test strips. The alternative method of testing lactic acid is the use of biosensors. Biosensors provide rapid, simple and direct measurement without the hassle of sample preparation.

A Biosensor is an integrated receptor-transducer device, which is capable of providing selective quantitative or semi-quantitative analytical information using a biological recognition element in direct spatial contact with transducer element. The first biosensor for lactic acid (L-lactate) was reported in 1970 by Wiliams et al. It was amperometric electrode with cytochrome b2 as biological sensing element with Fe(CN)63- as redox mediator.

The most common biological receptor for L-lactic acid is L-lactate oxidase (LOD) which catalyzes the reaction:

Senzytec instrument by Tectronik.Photograph courtesy of Tectronik Company

The main advantages of the lactate biosensor use are as follows:

Senzytec instrument by Tectronik.Photograph courtesy of Tectronik Company

The main advantages of the lactate biosensor use are as follows:

- Shortening the time of analysis

- Staff/personnel can be trained easily to use the assay

- Measurements can be done at the production site

- Cost of analysis is lower when compared with standard methods

- Biosensors based on electrochemical lactate detection: A comprehensive review -Kavita Ratheea, Vikas Dhullb, Rekha Dhulla, Sandeep Singha

- Ma‚gorzata Przybyt - Institute of General Food Chemistry, Lodz University of Technology Stefanowskiego, Lodz, Poland

- Investigation into immobilisation of lactate oxidase to improve stability B. Lillis, C. Grogan, H. Berney, W.A. Lane